Paper pulp packaging happens to be a core target for businesses globally since they shift far from unsustainable supplies towards eco-friendly answers. Molded pulp packaging offers a sustainable and price-successful way to provide large-top quality packaging that may be customizable and biodegradable. just one area driving innovation will be the introduction of substantial-effectiveness pulp molding device, like the Dwellpac Semi-Hotpress equipment. These equipment support enterprises streamline manufacturing although making certain precision and reliability.This article will discover the key characteristics of high-effectiveness pulp molding devices, upkeep techniques for lengthy-time period use, strategies to cut expenditures though maximizing output, And the way automation enhances creation and top quality. irrespective of whether you happen to be a business proprietor or possibly a packaging Expert, you'll achieve important insights that can help improve your production method.

Table of contents:

essential capabilities of large-Efficiency Pulp Molding devices

routine maintenance tricks for very long-expression device efficiency

Price-preserving methods in manufacturing

How Automation Improves Output and Quality

crucial options of large-Efficiency Pulp Molding devices

significant-efficiency pulp molding machines are revolutionizing how molded pulp makers work. The Dwellpac Semi-Hotpress Machine is one these kinds of case in point. It stands out for its Superior Management technique, high clamping precision, and seamless hydraulic general performance. With functions like precision shaping and eco-welcoming mould urgent know-how, it makes certain that every eco-helpful box packaging product is consistent in excellent and longevity. This is vital for industries needing customized answers like food stuff packaging, electronics, and industrial parts. these kinds of devices also help A selection of custom made molded pulp packaging desires, supplying major flexibility in generation.

upkeep methods for extensive-time period equipment overall performance

sustaining a pulp molding machine is crucial to ensuring dependable output and maximizing its lifespan. standard upkeep jobs include things like cleansing the molding surfaces, inspecting hydraulic devices for don and tear, and ensuring the control process is updated for peak overall performance. The Dwellpac machine is created to simplify these processes, enabling molded pulp manufacturers to streamline maintenance. normal inspections and proactive care not merely reduce sudden breakdowns but additionally assist maintain the precision benchmarks necessary for substantial-high-quality paper pulp packaging.

Charge-preserving approaches in creation

Charge-usefulness is a first-rate issue for molded pulp brands. to save lots of expenditures even though keeping high-quality, they can improve substance usage by leveraging effective pulp mould urgent technological innovation to attenuate squander, invest in Strength-economical equipment much like the Dwellpac Semi-Hotpress Machine to reduce Electricity usage, and practice team to totally make the most of Innovative machines to stay away from glitches that lead to inconsistencies or wastage. On top of that, buying eco-welcoming materials in bulk will help reap the benefits of reduce charges and reduce In general creation charges. By adopting these strategies, brands can stay aggressive although offering high-high quality, customized eco-pleasant packaging to clients.

How Automation enhances Output and top quality

Automation is now a pivotal part of modern manufacturing procedures. State-of-the-art pulp molding device suppliers, like Dwellpac, integrate automation to reinforce operational performance. automatic units, by together with capabilities like intuitive Management panels and authentic-time precision monitoring, decrease the chance of human errors. This ensures that just about every mould made satisfies rigorous quality expectations. With automation, companies may cope with substantial-scale production operates more proficiently, Conference precise deadlines when developing molded fiber packaging at aggressive fees. Furthermore, the dependable top quality realized through automation reinforces client belief in eco-helpful packaging answers.

significant-efficiency pulp molding equipment are enabling organizations to satisfy raising desire for sustainable packaging options. By investing in Highly developed systems, firms can click here generate tailored molded paper pulp items that don't just guard the surroundings but will also offer exceptional performance and toughness. With progressive machines and considerate servicing techniques, businesses can get over production problems, decrease operational prices, and present eco-welcoming items that cater to world sustainability targets.

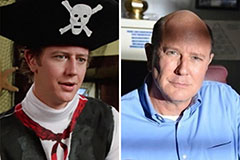

Taran Noah Smith Then & Now!

Taran Noah Smith Then & Now! Josh Saviano Then & Now!

Josh Saviano Then & Now! Judge Reinhold Then & Now!

Judge Reinhold Then & Now! Jennifer Love Hewitt Then & Now!

Jennifer Love Hewitt Then & Now! Meadow Walker Then & Now!

Meadow Walker Then & Now!